Two Seat Safari Kit Helicopter

Canadian Home Rotors – Newsletter “Excel-lent Times” November 1992 # 0002

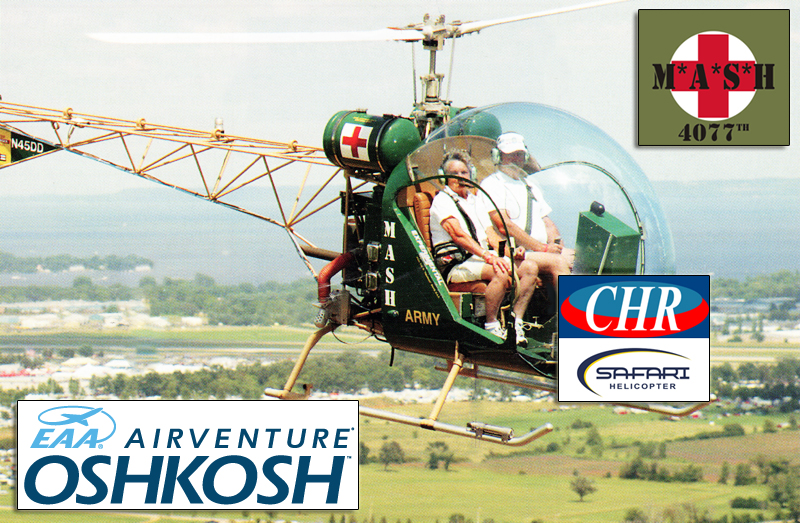

Canadian Home Rotors Inc. At Oshkosh 92′

The time; July 31, 1992

The place; Oshkosh, Wisconsin

The occasion; EAA Convention

The event; Canadian Home Rotors Inc. landed on the scene, giving the Rotorcraft World a better helicopter! Yes, our Grand Opening was a great success and we made many new friends including RotorWay owners who we found to be honest and open with their opinions. We met many of our old friends too!

It was nice to put a face with a voice as so much of our business is done by phone or fax. We have been told this was the busiest Oshkosh ever for the number of people attending and rotorcraft flying. No helicopter flew more than the BABY BELLE, as it was dubbed by the show announcer.

N3338T is the registration number of our demo machine, the Canadian Home Rotors Baby Belle and it flew constantly despite a recurring crack in the exhaust manifold.(A part we didn’t make).

This 47 look got a great response from the crowd giving us reason to offer this model. We have also decided to include welded fuselages as an option as it seems few are willing to try their hand at welding.

This fear is unfounded if you practice before starting construction. We gave a few rides to friends and customers even though we were somewhat limited by the EAA rules and regulations. All were impressed by the helicopter that just wouldn’t stay on the ground.

We brought three aircraft all together, the Canadian Home Rotors BABY BELLE model, an airworthy Commuter II owned by our good friend Curtis Eriksson of Alaska and one static helicopter frame to demonstrate/display the flight controls and our main components.

We encouraged everyone to sit in and fly the static helicopter frame around the tent, with vocal sounds being optional. It proved to be a big success with the kids of the forty year old variety. We also brought one complete kit in shipping crates to show just how well packed they are for shipping to you.

Two of our customers took us up on our proposal for FREE main rotor pitch change arms by bringing their helicopters to Oshkosh.

Larry Dingier drove all the way from Texas and then came home with us for an upgrade of his Helicom helicopter (more about him later). David Glassmeyer brought his single seat, an Emigh (Helicom) original and is planning to fly it again with our main rotor blades that he bought during the airshow.

This man owns two of these helicopters proving he has a very patient wife. Chris Nelsen is our newest builder/friend who we enjoyed meeting. We never lost Chris at night with his strobe on the back of his bike. An EXCEL-lent feature for making yourself easy to see.

The staff at Canadian Home Rotors Inc. will do all we can to keep our customers happy. After all, Safe and Satisfied customers are our best form of advertising. Call us for builders in your area.

During the evenings, we invited most everyone back to our campsite for some Chopper Chatter which gave us time to get to know them better and answer more of their questions in detail. Of course we were quite inexperienced, but demonstrated to all that we were friendly, yet professional and have been welcomed back next year by the EAA officials.

We hope to see you at Sun-N-Fun 93 and Oshkosh again.

The first step in readying one of the CHR factory helicopters for the trip home to Canada. AirVenture (Oshkosh) is the last of the summer shows for the members of this team. President, Murray Sweet hand directs Mark Richards, designer and Chief Pilot, as he brings in the ship to its platform on the back of Murray’s pickup. Next the helicopter will be turned so its tail overhangs the truck’s cab. The CHR caravan, – with other vehicles and ships traveling together, makes a most unusual sight driving across the upper Wisconsin, Minnesota and Canadian roads.

Everyone here at C.H.R.I, wishes to Thank all of you who took the time to visit and meet with us at Oshkosh.

Canadian Home Rotors BABY BELLE at Oshkosh 92

Larry Dingier arrives in Ear Falls

Our past readers will remember Mr. Larry Dingier purchased a used Helicom helicopter and is upgrading with our help. Well he made the long drive and met us at Oshkosh. But that’s not all, he then followed us home and stayed for three fun filled weeks.

Everybody pitched in and Worked to get his machine in the air. Larry has an air about him that makes him everyone’s friend and Ear Falls residents are still asking how cousin Larry is doing and if he will be returning.

Although Larry still has a lot work to do, we did get a picture of his Canadian Home Rotors helicopter hovering with 4 (yes I did say 4) people on it. Two people in the seats one on each skid.

Now please don’t try this at home as it is very dangerous. (Actually, we were just doing a run up with pitch to check vibration levels and never expected to get off the ground.)

Its definitely the most powerful Helicom based helicopter our pilot has ever flown. Larry has a 160HP 0-320 D2C and it sure has the power. This engine has bigger intake runners then the others we’ve seen and maybe they make the difference. Using that power all the time is not recommended, but it sure is nice to have a pinch.

Curtis Eriksson’s helicopter airworthy

Mr. Eriksson purchased his helicopter some time back and promptly brought it up to us for inspection and upgrade. He was the first to take us up on our offer of shop space, free hospitality and we sure kept him busy.

Curt’s couple of days turned into a week allowing us to get to know him and his family. Although the helicopter looked ready to fly when he arrived, there was much to do.

The workmanship and finish on this helicopter was EXCEL-lent, making us proud to display it at our tent. After arriving home from the show, we then did a complete overhauling of the main transmission for Curtis to bring it up to our specifications and the checking of critical parts for correct tolerances.

He also had us upgrade his tail boom with our drive train to save weight and increase reliability. It was a pleasure for Mark to test this good looking helicopter.

The next adventure was for Doug to deliver this helicopter to Curtis in Alaska with a total distance of more than 11,000 km’s. The trip went trouble free and Doug stayed long enough to assist and acquaint Curtis with his pride and joy.

CANADIAN HOME ROTORS SAFARI KIT HELICOPTER DESCRIPTIONS

The following Main Components will have to be purchased from Canadian Home Rotors Inc. as they are not available from other sources and would be extremely difficult to make by the home builder.

The Hardware Kits on the next page are all available from other suppliers and are offered by C.H.R.I. as a convenience to our customers. You may or may not get a better price at your local supplier.

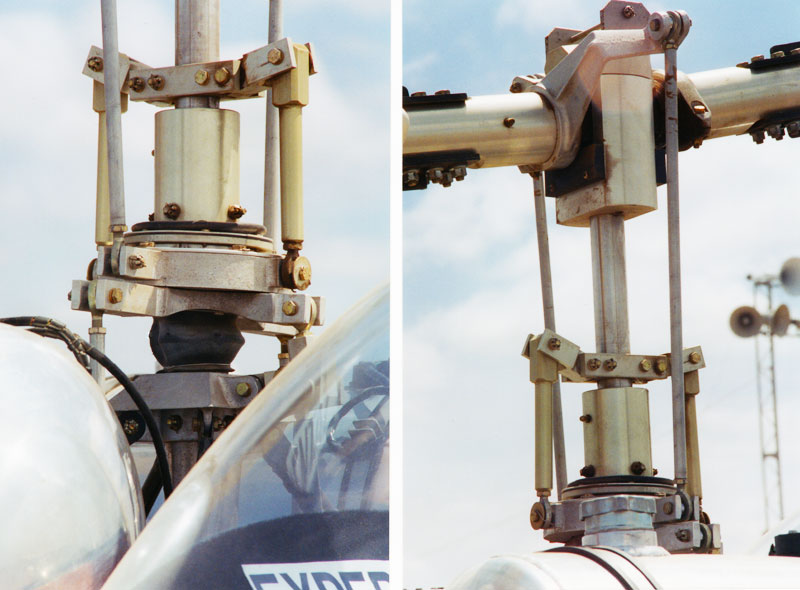

1. MAIN TRANSMISSION ASSEMBLY: Comes completely assembled ready to bolt on, includes swashplate, slider cross, over-running clutch, clutch drum (clutch lining already bonded and riveted), drive plate and cooling fan.

2. MAIN ROTOR BLADES: Comes bonded and riveted on leading edge. All that’s left to do is rivet trailing edge (pilot holes drilled, rivets supplied) and paint (or polish).

3. MAIN ROTOR HEAD ASSEMBLY: Comes complete ready to ream and bolt blades on (pilot holes drilled).

4. BALANCE BEAM KIT: Comes completely nickel plated with all rod ends control tubes necessary to bolt on head and main transmission.

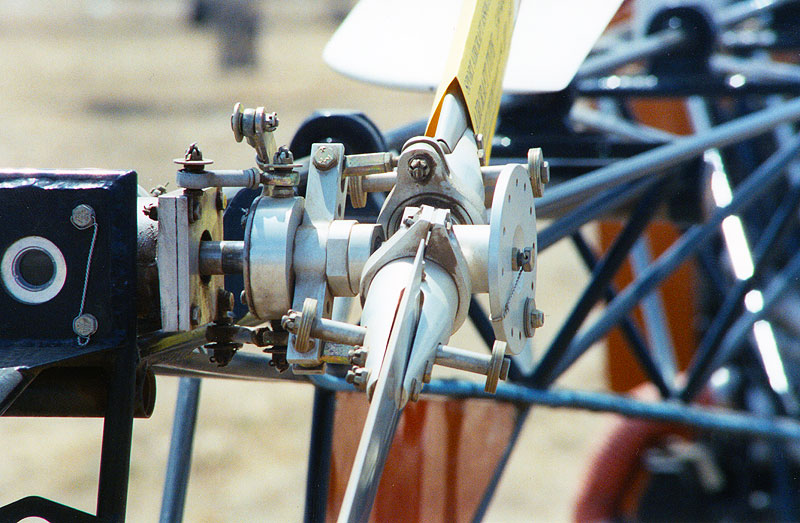

5. TAILROTOR DRIVESHAFT KIT: Contains pre-machined driveshaft, all couplings and pillow block bearings.

6. TAILROTOR GEARBOX: Comes completely assembled including sight glass and oil ready to bolt in.

7. TAILROTOR SWASHPLATE ASSEMBLY: Contains sealed swash bearing, slider sleeve with seals, all rod ends and links necessary for tailrotor pitch change.

8. TAILROTOR HEAD ASSEMBLY: Comes with stainless steel blades bolted on and balanced as a unit at factory.

NOTE: When paid for together, kits 6, 7 and 8 come assembled as one unit at no extra charge.

9. CONTROL MIXING KIT: Contains all rod ends, control tubes and cast aluminum bell cranks necessary to link controls to main rotor swashplate.

NOTE: All hardware (nuts,bolts and washers) necessary are included. Additionally, all parts in component kits are protected from corrosion by electroless nickel plating all steel parts and all machined aluminum parts are anodized. (Cast aluminum parts are not susceptible to corrosion due to high zinc content).

HARDWARE KIT DESCRIPTIONS

A. INSTRUMENT KIT: Contains all instruments required by FAA and some we feel are necessary for safe helicopter operation including;

-

Dual Engine and Rotor Tach

-

Helicopter Airspeed Indicator

-

Manifold Pressure

-

Sensitive Altimeter

-

Vertical Airspeed

-

Quad-Cylinder Head Temp

-

Compass

-

Bank Indicator

-

Quad-engine oil temp, Transmission temp, engine oil pressure and ammeter

-

Quad-Carb temp, Outside Air temp and two fuel levels

Also included, Hour Meter and all hardware necessary to install instruments.

B. FUEL SYSTEM KIT: Contains gasolator, fuel valve, fuel line, all fittings and clamps necessary to connect fuel tanks to carb. Also, finger strainers, fuel cap/neck, curtis drain valves, welding flanges and aluminum sheet used to make fuel tanks as well as hardware to mount tanks to frame.

C. CAB CONTROL KIT: Consist of cyclic pistol grips, collective grips, rod ends to complete throttle linkage, circuit breakers, electrical switches, mag switch, starter switches, carburetor heat and mixture T-handle cables, battery cables and terminals, master solenoid, mag wire and electrical wire.

D. FRAME TUBING KIT: Contains all 4130 steel tubing necessary to make helicopter frame and tail boom. Also, contains aluminum tubing for skids.

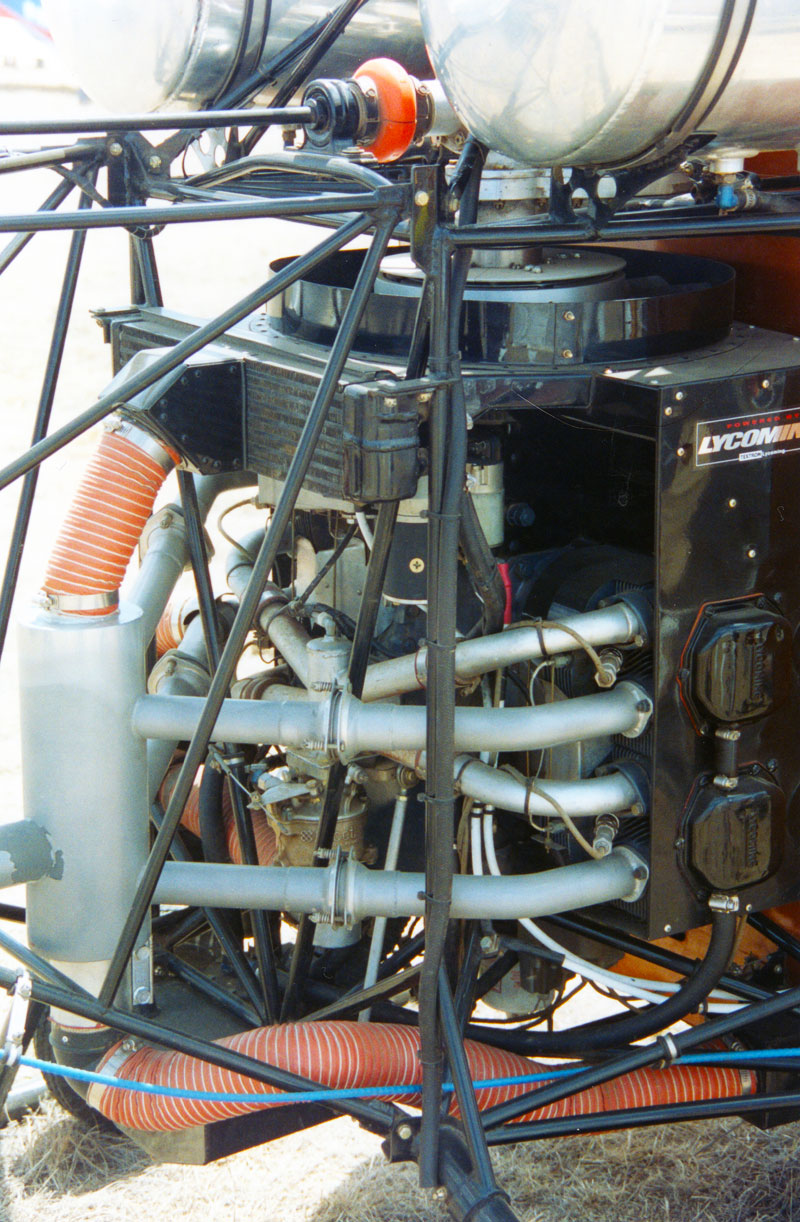

E. INTAKE MODIFICATION KIT: Consist of aluminum plate to cover original oil sump/manifold and 4130 steel tubing needed to make new intake manifold. This is required to run engine vertical and to save weight.

F. OIL SUMP MODIFICATION KIT: Contains all material to make new oil sump as well as fittings, hoses and clamps to complete the conversion of the Lycoming engine from horizontal to vertical. This kit also contains an oil cooler which will be required.

G. PRIMER KIT: Contains primer pump, nipples, fittings and tubing needed to install a primer system on the engine. This is recommended for easy starting, especially in cold climates.

H. TAIL ROTOR CONTROL KIT: Contains stainless steel cable, shackles, thimbles, turnbuckles, nicopress sleeves, control pulleys, nuts, bolts and washers needed to hook up tail rotor swash to pedals.

I. ENGINE DYNAMOUNT KIT: This kit has all rubber and hardware needed to mount an engine equipped with dynafocal mounts.

J. FIREWALL / COOLING SHROUD KIT: Contains all sheet aluminum, rivets and screws needed to construct a cooling shroud around the engine.

Most Asked Questions at Oshkosh

01. Question; What are the modifications required before installing the Lycoming 0-320 Aircraft engine?

Answer: The change consists of only replacing the oil sump with an aluminum plate and installing a separate intake manifold. This is to save on weight and allows the placement of the carburetor close to the engine. A separate oil sump is used below the engine.

02. Question; Have you had any reports of difficulty operating the Lycoming engine in the vertical position?

Answer: NONE.

03. Question; Would I be able to design and build my own cabin?

Answer: Yes, but we wish to make it known that weight and size will have to be a major consideration.

04. Question; What is used to weld the fuselage tubing together?

Answer: The air frame is designed for a welder of 50% proficiency using an Oxygen/Acetylene welding torch. A T.I.G. torch (Tungsten Inert Gas) system would be ideal but not required.

05. Question; Are you able to install dual controls?

Answer: Dual controls are a standard feature of our helicopter kit to help lower the flight training costs and prevent owners from trying to teach themselves to fly their helicopter. These can be removable.

06. Question; Are you able to get insurance for the helicopter?

Answer: YES. There is an insurance company working with Popular Rotorcraft Association that offers liability insurance costing about $500.00/year, in U.S. funds.

07. Question; What can I expect from Canadian Home Rotors for product support?

Answer: C.H.R.I. has slowly developed over 12 years with a large and ever growing client base of completely satisfied builders. We offer help and advice to anyone no matter what type of helicopter they own. Who knows, they may consider changing to ours at a later date or direct someone interested in our direction. Happy customers are our best form of advertising.

08. Question; What is your Time Before Overhaul (TBO) on the main components?

Answer: We recommend that our customers do major inspections at every 100 hours. The cost averages $350.00 for bearings and seals with a time frame of 40 man hours. Your time will lessen as you gain experience and remember that 100 hours per year is average for people who fly for recreational reasons.

09. Question; Do you use belts and chains in your drive train?

Answer: NO. The only belt used would be to drive the original alternator and there is not a chain on the aircraft We use a very simple and dependable gear-train with steel shafting to transmit the power.

10. Question; Is corrosion a problem?

Answer: C.H.R.I. has gone the extra step to prevent the deadly killer corrosion by having their steel parts Electroless Nickel plated and all machined aluminum parts Anodized.

11. Question; How long would it take for me to build the EXCEL 200 helicopter?

Answer: The average honest construction time is some 1,200 hours. Yes, we know others, are saying theirs can be built in 250 and 500 but the truth is told after talking with some of their customers.

12. Question; What are the flight operating costs?

Answer: You can expect to pay approximately $20 per flight hour depending on fuel and oil costs in your area and the type of flying done, hovering or cross-country.

13. Question; Would I be able to make payments for the parts I need?

Answer: C.H.R.I. has been accommodating our customers needs for more than 12 years and will continue to do so. Five have been making payments for 6 years. Ask!

14. Question; Is there detailed documentation to show how things are done?

Answer: YES. C.H.R.I. has developed extensive written material to assist with the Construction, Rigging, Flying, Maintenance and Over Hauling of your EXCEL 200.

15. Question; Who does the casting of your aluminum transmission housings?

Answer: C.H.R.I. does all of its own casting in-house to allow us to closely control the quality and costs.

16. Question; Can the EXCEL 200 home built helicopter kit be purchased in sub kits?

Answer: YES. C.H.R.I. will sell individual components allowing the customer to purchase the items as they can afford them.

17. Question; Do you offer Airworthiness Directives to your builders?

Answer: C.H.R.I. offers a FREE newsletter called “EXCEL-lent ADVISOR” that is used to inform our builders and owners of any safety related changes required. In addition, we provide construction tips, maintenance procedures with the intent of keeping everyone Safe and Flying.

18. Question; Do I have to install the Lycoming aircraft engine?

Answer: We would like to see this engine used as we have never had problems with the installation. Others have used the Franklin and Continental with success.

PLEASE CALL US ANY TIME AND WE WELL BE MORE THAN HAPPY TO ANSWER ALL OF YOUR QUESTIONS

NEW INFORMATION PACKS (1992)

Canadian Home Rotors Inc. is proud to announce that we now have a comprehensive information pack. Our information pack will include but is not limited to: A complete price list of our components and hardware kits. A description of these kits. A specifications sheet on our helicopter. An order form for our kits as well as our hats, T-shirts and video. A letter describing the EXCEL 200 flight characteristics as compared with commercial helicopters, written by our pilot.

A history of our company and helicopter design. One booklet on helicopter theory and aerodynamics. Also, one full color blow-up photo of one of our helicopters high over the Northern Ontario countryside suitable for framing.

Order yours today.

Satisfaction guaranteed – Canadian Home Rotors Information Pack $20.00 – NOTE:1992 PRICES!

Canadian Home Rotor Hats $9.50 (tie dyed flame with stitched logo) Canadian Home Rotor Shirts $11.00 (black, cotton/polyester, gold print)

Indicate size, medium, large or extra large SAVINGS UP to 20% DEPENDING ON THE EXCHANGE RATE OF THE U.S. DOLLAR TO OUR CANADIAN $.

CANADIAN HOME ROTORS INC.

Salve mi serve l’asse del rotore principale compreso la piastra oscillante come da foto e il rotore di coda mi potete dire il costo grazie.

EDITOR: Translation – “Hi I need the axis of the main rotor including the oscillating plate as pictured and the tail rotor you can tell me the cost thanks.”

We do not manufacture any parts though do sell some plans that “may suit” your needs?

Muy buenas tarde. les mando mucho saludos.soy de colombia soy tecnico de aviacion.muy interesado en un plano de contrucion. para fabricar un elicoptero.de los de ustede muchas gracia muy interesado de hablar con ustedes.por favor o escribirme.

Very good afternoon. I send you my best regards. I am from Colombia, I am an aviation technician. I am very interested in a construction plan. To make an elicopter. You are very interested in talking with you. Please or write me.

Glad you like the website, I get hundreds of requests to talk about helicopters, unfortunately there is only one of me and only 24 hours in a day. We will try to add more content for your enjoyment shortly. As always, I encourage you to contact your national or local sport aviation club for assistance.