The, CH-7 Angel helicopter, was designed by Italian born Argentina citizen Augusto Cicare. The CH-7 angel is his seventh helicopter creation, hence the acronym CH-7, which stands for Cicare’s helicopter #7.

The word Angel was added to the CH-7 by the Italian manufacture, Heli-Sport of Turin, Italy. The Heli-Sport company commissioned famous Italian automotive designer Mr. Marcello Gandini to style the cabin/cockpit for Mr. Cicare’s prototype. A few of Mr Gandini’s design credits include the Lamborghini Countache and Diablo sports cars.

Since the CH-7 flew like a little Angel, combined with the fact that Mr.Gandini previously designed the cosmetics for the Diablo (Diablo, Spanish for Devil), the manufacture decided that it only fitting to name the new aircraft the opposite of the word devil, so the name Angel was chosen – thus the CH-7 Angel Helicopter was born.

Augusto Cicare

Augusto Cicare turbine powered CH-6 helicopter prototype flight testing.

After 35 years of helicopter engineering, searching for an economical model, Augusto Cicare created in 1987 the CH-6 prototype, which in it’s evolutionary version the CH-7 Angel helicopter, is nowadays a milestone in helicopter history. He made his first homebuilt helicopter, a coaxial-rotor-conflgured craft, in 1955 at age 18. To this he added his own homebuilt power plant.

Cicare also taught himself to fly. One of his feats, the elimination of the swash plate, reduces the rotating parts in the main rotor and simplifies pilotage as much as mortify the last 50 years of helicopter engineering. To date his talented mind has created eight helicopters and one fully articulated simulator.

The Argentinian Air force funded and test flew the CH-6 with a thought of using such models for training purposes. Today the Argentinian and Brazilian Air Forces are utilizing his SVH-3 simulator for hover training which is based on the CH-7 Angel. Since 1992 he has provided licensing rights for the CH-7 Angel to Heli-Sport srl of Turin, Italy.

Barbero Brothers and Heli-Sport

After 7 years of manufacturing and over 120 CH-7 ANGEL helicopters flying all over the world, the Barbero brothers developed in 1996/97 the CH-7 KOMPRESS project. This turbo charged dual seat Angel, is suitable for training and capable of great performance seldom attained before by piston powered helicopters.

Pier Luigi Barbero is the driving force behind development and testing having attained over 2000 hours of flight on the CH-7 type. He works hand in hand with brother Josie, an Electrical and Mechanical Engineer in his own right. Business matters are handled by Claudio Barbero, who completes the management trio.

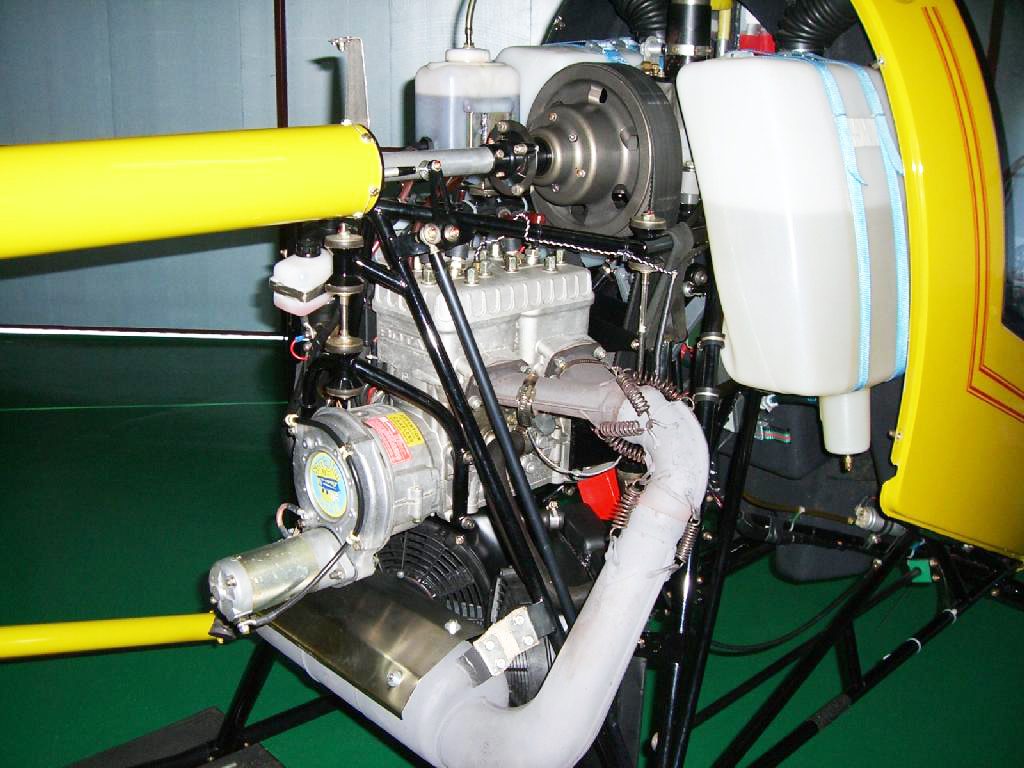

The CH-7 Angel helicopter Mechanics

The original Rotax 582 powered CH7 Angel helicopter mechanics. Note: the two stroke engine is no longer used on any production CH helicopter.

The CH-7 Angel helicopter is a conventionally configured helicopter with a main and anti-torque tail rotor. The airframe has a welded 4130 chromoly steel structure carrying the 64-hp Rotax 582 or 115-hp 914 T engine, rotor mast, transmission, tail rotor and the skid landing gear steel down tubes. Longitudinal skids are aluminium.

Because of the joint between the landing gear and the main fuselage, the bending forces of the landing gear are NOT transmitted into the main-fuselage. An impressive feature of the CH-7 frame is the triangles that are incorporated into the construction, the triangle being one of the strongest structures.

The steel airframe incorporates a 32-psi tube pressurized system monitored by a cockpit gauge to keep tabs on the helicopter frame’s integrity. This is a safety-related system not usually found in small helicopters. The Angel uses two off the shelf Fiat radiators plumbed in series with thermostatically controlled electric fans.

Main rotor blades are composite and are formed by winding strands of fiber filaments lengthwise around foam cores. Originally, the CH-7 Angel helicopter had symmetrical blades, but HeliSport has moved to an asymmetrical profile with a 6 degree twist, that has greatly improved performance. An asymmetrical airfoil is more efficient than a symmetrical air foil in that it will produce lift with a negative angle of attack. Blades are left unpainted, except for the weighted tips, to enable a see-through inspection.

Cicare’s simplified rotor system With fewer parts features a teeter type coning rotor with a semi-rigid head. The rotor head itself is made of steel, but the bearing head housing is aluminum. Lead-lag adjustments to the blades are through eccentric bushing in 0.025-inch increments.

The head, which contains elastomeric bushing for teetering, moves through 12 degrees positive pitch at full up collective, down to 2 degrees negative for auto rotation. Heli-Sport provides a fully assembled head in the kit. The manufacturer has eliminated the swash plate and, instead uses a direct spider system.

The clutch tensioning system is servo driven, an improved version of the R22 type helicopter and tensions a single five-groove, 50mm wide Goodyear wedged belt. The tail boom is an aluminium tube that carries a 32mm diameter drive shaft. Like the Robinson R22, the tail rotor pitch is controlled through push-pull tubes. The tail boom on the CH-7 Angel helicopter is supported by an ‘A frame’ structure, and only 3 feet of tail boom protrudes beyond the support.

Cicare also went out of his way to provide well a supported tail rotor drive. It is bolstered by two midway bearings, with the only unsupported area being the 990mm between the last bearing and the teeter-type tail rotor. Its blades are all metal, contain a spar, have a NACA 63014 symmetrical airfoil, and an 8 degrees twist.

The design of cockpit is credited to Marcello Gandini”an internationally recognized Italian designer who has blueprinted numerous Italian, German and French sports cars, trucks and custom vehicles. The cockpit and canopy layout of the CH-7 Angel helicopter give superb panoramic visibility. The canopy swings up and pivots down slightly for main rotor clearance. Inside, the cockpit has a width ot 755mm, and a 6 toot pilot can be seated without his head striking the canopy.

The voyage of discovery

Augusto Cicare’s original swash control invention – pre-Mini-500. Some very clever engineering that resulted in more stable flight and control.

Turin is a bustling industrial city, home to manufacturers such as Fiat Automotive. Angel owner Dave Maree and I travelled to northwest Italy to experience first hand the legend of the Kompress.

Contained in what might have once been a rambling Italian villa is today the CH-7 Helicopter factory and assembly plant. One first encounters the showroom containing the CH-7 Angel prototype. In most respects the helicopter is almost identical to the latest deliveries of single seat Angels.

Any differences are subtle except the original aluminum symmetrical rotor blades used in the early testing phase. Interesting to note that the prototype has flown over 2000 hours and is now retired as a showpiece but is as airworthy as ever.

We received a warm welcome from Heli-sport MD Claudio Barbero. After a strong cup of “cafe”, enough to put two travel weary South African boys on the right track, it was time to visit the production area. The first impression is usually the lasting one. The factory is spotlessly clean and tidy. We were shown racks of packed and labeled components ready for dispatch to various countries around the globe.

We start with the assembly line where many components are manufactured by contracting companies and supplied ready for assembly to Heli-Sport. Control linkages are being attached to the airframe, fuel systems are installed, power plants fitted and electrical systems connected.

We observe seasoned technicians assembling the main and tail rotor gearboxes and bench balancing tail rotor blades. Cabin moldings are trimmed for fitment and the resultant assemblies are taking the form of new flying machines.

The helicopter rotor blades are, meticulously engineered on sight. During the curing phase the blades assume their slight twist, the design of the moulds having compensated for this.

The CH-7 Angel helicopter flight-test

We are met at the breakfast table by Pierre Luigi – chief instructor and test pilot for CH-7 Heli-sport. The day didn’t hold out much promise for flight, as the mist had settled in solidly across the farmlands. We drove in hope of a break in the weather and the highlight of the trip – to fly the CH-7 Kompress helicopter.

The training and service facility, on the outskirts of Asti, tests new aircraft freshly off the production line in Turin. Initial engine startups are under the supervision of Rotax Italy. Fuel and electric systems are monitored and blades are tracked and balanced. Flight instruction averages one hundred hours per month on each of three dedicated training helicopters. Three instructors help to share the student load. Registered in the experimental class, the CH-7 Angel helicopter student requires 30 hours of flight training to quality and a further 30 hours of solo time is required before a passenger may be taken on board.

With the instructor seated at the rear, I climb aboard and with careful foot placement, I slip into the pilot seat. As the seating is a tandem arrangement I was interested to determine whether the cabin was comfortable enough when two six foot men occupied the space. As Luigi already had his feet on the dual control pedals on either side of me I had to reach over his left leg to operate the throttle and collective lever. The fighter-style canopy was moved up and back to seal us off from the elements.

With my lap harness adjusted, Luigi proceeded to run through the start sequence. Master, magnetos, start and the 914 Turbo comes smoothly to life. After clutch engagement, she is warmed up to 50 degrees for about 2 minutes before bringing her up to 100%.We then checked both mags and the free-wheeling clutch, governor on, we’re ready for lift off.

In the hover, engine RPM is effortlessly maintained by the governor. Transition is smooth as we head for a nearby field for square bashing exercises. Hovering the CH-7 Angel helicopter is surprisingly less demanding than the R-22.The high inertia rotor system coupled with an extremely responsive power supply makes the Kompress a forgiving machine to fly with exceptional tail rotor authority.

As we transition into forward flight with the slightest nudging of the cyclic I lift a little too much collective and we’re climbing out in a similar fashion to the Bell 205, rotor and engine rpm still at top of green. With a bit of directional guidance from Luigi we’re heading out to open farmland, the odometer comfortable at 110mph, the machine is well balanced, the cyclic smooth.

Luigi indicates towards a lush green field framed between rows of neat trees. This is our “LZ”. As we angle in setting our attitude, collective eased downward and a glance over the T’s and P’s – all in the green. Smooth transition into a hover and touchdown in the soft pasture. A few attempts at landing were needed to consistently touch down smoothly.

I ask Luigi to demonstrate her power, as I watch the manifold pressure needle steadily rise to the top of green +- 35 inches as I observe the VSI push to 1500ft/ min climb. The ground falls away quickly as we pull up to the cloud base. I’m quite stunned at the performance.

In auto-rotation the cyclic control is as responsive as in powered flight. Before touchdown I raise the collective and roll power on, feeling very comfortable with the remaining inertia in the rotor. The CH-7 has high inertia blades, which is a great safety factor and the low weight contributed to the gentle descent (500fpm). I realize this is a very capable machine. Somehow I am reminded of the much larger Jetranger for power. Our landing is neat and gentle. Cool-down takes 90 seconds to 2 minutes in two stages: first, at 75% engine rpm, then at idle.

As for the seating arrangement? – I will have to return to Italy to determine whether the back seat is comfortable enough!

CH-7 Angel Helicopter Summary

The “cabinless” CH-7 also known as the CH-6 prototype helicopter.

For the rotor wing enthusiast who is looking for an affordable, reliable helicopter which is stylishly designed, meticulously engineered, with ample turbo performance in the form of a full assembly kit, one should seriously consider a Kompress. Heli-Sport has achieved their goal- to manufacture the best, most advanced homebuilt helicopter possible, which is designed to fly.

One of the many new releases that followed the original CH-7 helicopter. Here we see the two seat CH77 RANABOT Helicopter.

Specifications for the CH-7 Angel

| CH-7 Angel Helicopter Manufacture and Designer | |

|---|---|

| EliSport/AeroSport | Augusto Cicare (mechanical) |

| Marcello Gandini (cabin) | Strada Traforo del Pino, 104, 10132 Torino Italy Phone: 39-11-8996730 Fax: 39-11-8995550 |

| CH-7 Angel Helicopter Air Frame | |

|---|---|

| Crew | One |

| Fuselage Length | 175″ |

| Fuselage Width | 32 1/4″ |

| Over All Length | 22’5″ |

| Skid Width | 6′ 4″ |

| Max height (mast or empinage) | 73″ @ Mast |

| Gross Weight | 792Lbs |

| Empty Weight | 451Lbs |

| Useful Load | 341Lbs |

| Tail Boom Structure | Aluminum Tube, Aprox 4″ dia. |

| Tail Boom Support | A frame brace |

| Length of Boom Behind Support | 36 inches |

| Tail Rotor Control Linkage | Push Pull Rods & Bell Crank |

| Canopy | Lexan, One Piece, Forward Hinging |

| Hours Between Overhauls | 1000 hours (or on condition as fleet matures) |

| Air Frame Construction | 4130 Chrome Molly Tubing – Pressurized with nitrogen gas to detect defects at a glance. |

| CH-7 Angel Helicopter Flight Data/Performance | |

|---|---|

| Max Speed (VNE) | 92 MPH |

| Cruise Speed | between 75 & 85 MPH |

| Best Rate of Climb Speed | 1100 FPM |

| Max Duration Speed (best fuel economy) | 68 MPH |

| Max Duration Time | 2.5 hours (no reserve) |

| Max In Ground Effect Hover | 7,500 feet |

| Max Out of Ground Effect Hover | 5,500 feet |

| Service Ceiling | 11,000 feet |

| CH-7 Angel Helicopter Main Rotor System | |

|---|---|

| Number of Blades | 2 |

| Construction | Composite, 1.5 kilo tip weight |

| Diameter | 20 feet 3 inches |

| Main Rotor Air Foil | Asymmetrical |

| Degree of Twist in Blade | ? To Be Advised |

| Blade Chord | 7 inches |

| Rotor RPM | 520-Top of Green |

| Tip Speed | ? To Be Advised |

| Articulation | Teetering, Semi Ridged |

| CH-7 Angel Helicopter Tail Rotor System | |

|---|---|

| Number of Blades | 2 |

| Diameter | 38 5/16 inchs |

| Air Foil | Symmetrical |

| Degree of Twist in Blade | ? To Be Advised |

| Blade Chord | 3 15/16 inches |

| Rotor RPM | 2808-Top of Green |

| Tip Speed | ??? FPS or ??? MPH |

| Articulation | Teetering, Semi Ridged |

| Pre cone Angle | ? degrees |

| CH-7 Angel Helicopter Factory Standard Engine – (2004) | |

|---|---|

| Engine | Rotax 582 |

| Fuel | Unleaded Auto Fuel-90 octane or better |

| Weight | 86.6 Lbs |

| Horse Power | 64.4 hp SAE @ 6500 RPMs |

| Max RPMs | 6800 |

| Horse Power to weight ratio |

1 hp for every 7.003 Lbs for every pound of empty weight |

| Displacement, (cubic centimeter) |

580 |

| Number of Cylinders | 2 |

| Power Cycle | 2 Cycle |

| Lubrication | Oil Injection Pump |

| Ignition System | Dual (two plugs per cylinder) |

| Cooling System | Liquid/Water |

| Radiators | 2 plumbed in series mounted in a V across the frame under the rear of the engine |

| Cooling Fan | Yes, 2 |

| Type Fan | Electric fans/when needed |

| Time Between Overhauls |

Rotax Recommends 500 hours, HOWEVER, Powering a helicopter EXPECT to half this Number. |

| CH-7 Angel Helicopter Power Transfer Systems | |

|---|---|

| Clutch | Mechanical/Cable |

| Engine to Transmission | Single – 4″-5 groove, GoodYear belt |

| Transmission to Tail Rotor | 1 5/16″ diameter aluminum drive shaft support by 2 intermediate bearings supporting the TR shaft |

| CH-7 Angel Helicopter Standard Equipment | |

|---|---|

| Quad Main Rotor Transmission | 2 EGT, Engine Coolant Temperatures |

| Dual Rotor/Engine Tachometer | Vertical Speed Indicator |

| Non Sensitive Altimeter | Ground Handling Wheels |

| Air Speed Indicators | |

Average Building time 200 hours (85 hours by factory)

CH-7 Angel Helicopter Owners Comments

The CH-7 Angel Helicopter has a few unique features that seem to set it ahead of the pack.

- First: The EliSport Team designed the airframe to have both a pressure gage and inlet port. This unique feature allows the pilot to check for any cracking of the air frame by noting the continued nitrogen (an inert and dry gas) pressure in the air frame during pre flight.

- Second: Asymmetrical/Composite main rotor blades. An Asymmetrical air foil is a more efficient airfoil than design than a symmetrical air foil.

- Third: Also, one more important feature the EliSport company has included or perhaps not included in the CH-7 Angel’s main rotor blades, they only paint the tip and root. The owners of EliSport explained to me that by not painting the blades one can hold a shop light behind one side of the blade and easily check the blades structural integrity by looking through the translucent blade. EliSport went on to explain that paint a blade could possibly hide important/lethal changes in the blade as they age. Kind of like bondo and new paint on a used car.

- Forth: Using electrical fans on the CH-7 Angel’s cooling system that are thermostatically controlled to only rob power from the engine when needed. A mechanical fan or fans are constantly drawing some what critical power from the engine that could be used to propel the helicopter. The mechanical system (one would think) also causes a slightly longer warm up time. Also, having the engine only partially enclosed aids in cooling the Angel’s power plant.

- Fifth: Lower center of gravity and over all height. This feature should lessen the chance for dynamic roll over on the CH-7 Angel Helicopter along with allowing the Angel to be stored in garages with lower door and ceiling heights.

- Sixth: The tail boom on EliSport’s CH-7 Angel Helicopter is supported by an A frame structure and only 3 feet of tail boom protrudes beyond the support.

- Seventh: The cockpit and canopy layout of the CH-7 Angel give superb/panoramic visibility not to mention the fighter pilot like feel one gets when flying an Angel.

- Eighth: Since the CH-7 Angel’s canopy is hinged in the nose and swings forward, the pilot can step up on the seat and closely inspect the rotor head with out a ladder.

CH-7 Angel Helicopter Kit Owners Reports

I own a CH-7 Angel Helicopter, her name is Miss Nina and at this time (June 18, 1996) she has 63.6 hours on her. I ordered her from the factory in Torino Italy sometime in July of 1994. I actually received her in a 4 1/2 by 4/12 by 10 1/2 foot long wooden crate around the end of the same month, all the way from Italy (with a slight detour to Chicago).

She took about 2 months/200 hours to go from that heavy wooden box full of parts, to the shiny new, sleek and sexy (I have been told that all parents think there children are beautiful) piece of Italian mechanical flying art work called the CH-7 Angel helicopter.

Construction was straight forward, nothing really technical. The manuals were adequate, but not perfect. The only welding to be done was the muffler mounting brackets and heat shield (the factory never sees the muffler). The Angel is an assembly kit, there actually is no fabrication to be done other than the muffler brackets.

I ended up painting her fiberglass body parts yellow, the tail boom and frame black (because the frame is charged with pressurized nitrogen gas in order to check for cracks, I saw no need to paint the frame a light color in order to easily check for problems manually/optically). Aside from the yellow and black, I ended up Jet Hotting (an almost chrome like, heat resistant coating that with stands up to 1,100 degrees f in temperature) the 4 gear legs, the tail rotor pedals and cyclic along with the muffler. Now looking back and seeing how virtually all other Rotax mufflers I have seen to date look old and rusty after only a few hours, I am extremely pleased with the Jet Hot process.

I must candidly admit that I didn’t do it (assemble her) alone, I had some help. I did the majority of the work, however Cliff Haley and Emil Rolondo contribute lots of help and perhaps more importantly, lots of mental support (after all, I was the type of kid that did not like to assemble models as a boy, so the mental support was a must as far as being a confidence builder).

I must also candidly admit I also had difficulty with the final balancing of Nina’s main rotor system. I, with the help of another friend, Bob Keiper (a radio control model helicopter pilot and a professional Rotax/2 cycle engine mechanic) went through the assembly manual word for word following the static balancing. At the end of the procedures, we determined the rotors needed 13 grams (yes that little) of additional weight added to one tip to balance Nina’s rotors. Any way, being candid, I was a tad leery of adding that much additional weight to one tip. This being the case combined with the fact that I decided to play it safe and ask the manufacture first (there only reply was “No, remove it from the other tip”, with no hint of how to safely remove this much weight).

As it was, I don’t think I ever spun her up with the additional weight I did however locate two prows that seemed both eager and capable to help.

The first gentleman was a Rotorway guru, a Mr. Ron Froberg of Hartzel Alabama. He and I went over my Miss Nina CH-7 Angel Helicopter with the proverbial fine tooth comb. Happy to report, the out come was, almost no problems.

The second gentleman w as Mr. Norman Suranno of ?????? Georgia. Norm is a balancing expert with ????? years of experience, both Military and civilian that now has formed his own balancing company, somewhat specializing in the Experimental aircraft segment and is now off on his own any way, after attaching his transducers on Nina’s frame and me running her up. Norm penciled out that I should add 12.7 grams to the same blade I thought I should add 13 grams too. However he suggested we swap the blades grip for grip. That was it, I was in the air. Miss Nina took to the air for the first time on March 10th, 1994 at the age of 4.1 hours on her hour meter.

Being completely above board with my experience concerning the CH-7 Angel, yes I had my moments of frustration. After all, I had her finished in October of 1994 but didn’t get her in the air until March of 1995. In hind sight, taking into consideration I was a first time builder, things actually went good.

Life With an CH-7 Angel Helicopter

As I mentioned in the beginning of this, I have lived with my Angel for 63 flying hours now. As any relationship, it hasn’t been totally perfect. At about ?????? hours I discovered the rear cylinder wall/piston to have an excessive amount of scratches as Bob Keiper and I were replacing the rotary valve seal on Nina’s 582 Rotax power plant. Upon discovering the scoring, I chose to bag my attempt of replace both the rotary valve and now the piston. I ended up having both chores done by a pro (Green Sky Aviation/Rotax of Ohio).

Since Green Sky is some 300 plus miles from my Pocono Mountain home in North eastern Pennsylvania, the Green Sky guys did a “while you wait” job on Miss Nina heart. I dropped it off one afternoon, got a motel and picked it up the next afternoon.

All in all, I am very pleased with my Angel. I actually sometimes forget I own a helicopter and find my self a tad surprised as my thoughts drift off as I wait for the door of my garage door to open and expose my sexy Miss Nina (the name I have chosen for my helicopter). More than once I have caught my self thinking “hey, you own that cute little flying machine”.

I fly her mostly for fun. However, when ever possible, I make my bi weekly banking trips for my small business in her, landing behind the bank (ironically near the drive up windows). I have also flown her to the post office on one occasion. The post master had a big grin on her face and told me I was welcome to fly in any time I like.

Like I said, all in all, I am happy with my CH-7 Angel helicopter. Being candid with my self, owning any single seater was not my first choice. However, as every one, today I am older than I have ever been (46 now). This being the case, the chances were slim that I would ever own that R44 I planning on. Now, I must say that I haven’t given up on the R44 dream. I hope to have the extra quarter million + it would take for the 44, but I must admit because of the styling and agility of the Angel and more importantly the urgency of NOW (realizing one’s tomorrows could stop arriving with out warning), I’m having a blast only being able to take my most important passenger along in the CH-7 Angel.

Be the first to comment on "Evolution Of The CH-7 Angel Helicopter"