Certified Two Seat Helicopter

The Robinson R22 helicopter is fast,simple, tough and reliable – Doesn’t everybody know that?

ARTICLE DATE: March 1990

MANY HELICOPTER PILOTS WHO HAVE not flown the little Robinson R22 helicopter are prejudiced against it, but pilots who have been at the controls like the compact two-seater. Why must this decade-old helicopter still prove itself in flight before being accepted?

The Robinson has had to earn its acceptance simply because it is different—it has many unusual design features and is the smallest production helicopter around. The R22 was also stigmatized by two failures of the main rotor blade early in its production life.

The causes of both problems were quickly identified and corrected, and all the blades were replaced, generating a clean record for the past decade. But some helicopter pilots never forget. I did not learn to fly helicopters in the U.S. Army, as have most helicopter pilots, but I was trained by Army instructors in the Army way.

Along with learning to fly autorotations to touchdown and constantly fretting over stuck pedals, I learned to trust the familiar helicopters from Bell and Hughes, Schweizer’s TH-55/300C and anything built by Sikorsky.

But not the Robinson. It didn’t matter that there were problems and limitations with other familiar names; we knew those problems and believed we knew how to avoid them.

The R22 helicopter had never been in the military, and in the helicopter world, that’s as rare as pink underwear in the barracks. I’m embarrassed that I took such a jaundiced view of the R22 for so many years instead of flying it to see for myself. Now that I’ve flown it, I can say that the little Robinson is a blast.

It does everything the company promises, and priced at about $100,000 it is probably the most affordable helicopter in the world. It’s also the biggest seller: some 1,600 have been built to date, and of those more than 200 were built last year, totaling about 75 percent of the piston-powered helicopter market for 1989.

About two-thirds of all R22s built last year were shipped outside the U.S. Frank Robinson began his design work on the R22 in the mid-1970s, after he had worked as an engineer designing helicopters for more than half a dozen companies.

An IFR panel (top left) makes the R22 a popular instrument trainer. The asymmetrical tail rotor airfoil (top right) is most efficient, and the engine (above) a cinch to preflight.

But during his tenure working for others, he couldn’t build enthusiasm for a small, personal helicopter. Most companies were interested in military contracts—the fairy godmother of all helicopter creation—so Robinson decided to design and build a personal helicopter himself.

The R22 helicopter first flew in 1975 and was certified in 1979. The company was perpetually underfunded, but Robinson refused to yield control or to deviate from his vision of a lightweight, low-cost helicopter.

Though he accepted a few investors in the early days, the company is now totally under his control, Weight and cost were twin enemies of the R22 from day one. If its weight increased, a larger engine would be needed, more fuel would be required and larger and more complex structures would be necessary to support the weight.

If its size and complexity increased, so would its cost. Robinson is a man who thinks in terms of ounces or grams, not pounds. An R22 Beta, the current model, weighs just 826 pounds empty—and every ounce counts.

The R22 helicopter has a conventional metal structure. The cabin is a riveted aluminum frame with a composite skin. The basic frame is welded steel tube supporting the engine, landing gear and main rotor mast.

The tail boom is an aluminum monocoque tube. Walking through the factory with Robinson, I was impressed by the conservative nature of the helicopter design and the high degree of precision machining used. More than a dozen different steel alloys are used for various parts, depending on the stress requirements.

Robinson points out that he is able to use more exotic alloys than many larger helicopter manufacturers because his parts are so small. The cost per pound of the material has little impact on the overall cost, so he has tried to select optimum metals for each part.

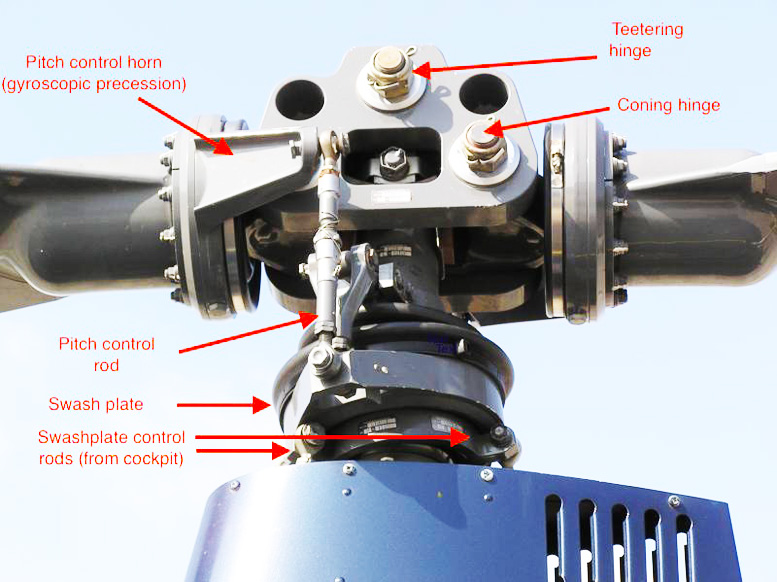

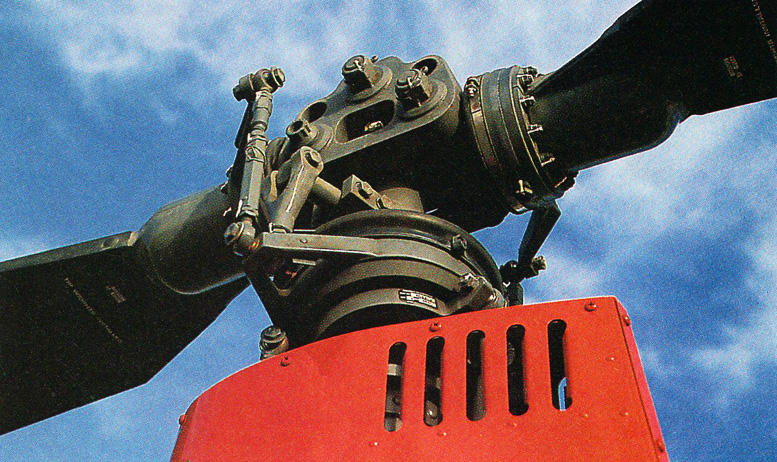

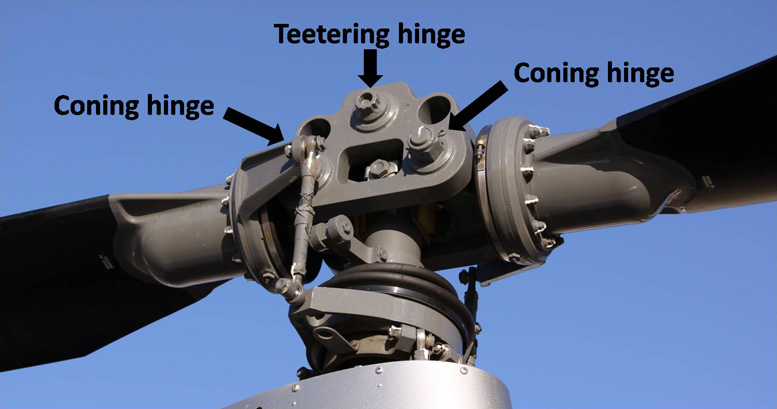

For simplicity of manufacture, maintenance and storage, Robinson chose the two-blade teetering-rotor system similar to that used on many Bell helicopters. But the R22 rotor head is different; it’s a Robinson-patented Tri-hinge design.

The R22 rotor hub is hinged at the top, allowing the blades to flap up and down teeter-totter fashion just as they do in a Bell. Main rotor blades on any helicopter also have another phenomenon known as coning.

When a main rotor is loaded, the blades flex upward, converting the rotor disc into a cone, and changing the pitch of the blades. But main rotor pitch control is the primary flight control of a helicopter, so control of blade pitch must be maintained regardless of blade coning.

Bell overcomes the tendency of blades to change pitch during coning by using hydraulic boost on the main rotor controls. Hydraulics work fine, but they’re far too heavy and costly for the R22.

So Robinson designed coning hinges into his rotor head, allowing the blades to cone without exerting undue pitch-change force. The coning hinges are the other two pivot points that—along with the central teetering hinge—make up the Tri-hinge rotor head.

The Tri-hinge rotor head is so effective that the R22 can be easily flown with fingertip touch and without trimming to unload the cyclic. In cruise, however, there is a slight pull to the left and a cruise-trim spring system is used to neutralize cyclic force.

Teflon bearings in the rotor head need lubrication every 2,000 hours, which is just in time for the airframe’s recommended overhaul. In fact, all bearings on the R22 are either Teflon-coated or -sealed and need no lubing between overhauls.

The main rotor blades are made up of a bonded aluminum skin over aluminum honeycomb, with a triangular stainless-steel leading edge. The steel adds strength to the blade and provides excellent resistance to leading-edge erosion caused by dirt, rain or bugs.

The blades can even slice through small birds without denting the leading edge. The tragic bonding failure on the main blade of the third R22 helicopter built was traced to contamination of the blade surfaces before the adhesive was applied.

Strict quality control has eliminated that problem, and small segments of every blade are cut off and pulled apart to test the integrity of the bond. One out of every 50 new blades is randomly selected and tested to destruction. The only other blade failure occurred in 1981 when a root fitting cracked.

The FAA-mandated testing during the aircraft’s certification process had failed to reveal that a relatively tight radius curve in the fitting would fatigue. All blades were replaced with a new design, and blade integrity has so far been perfect.

Because the bearings are grease-free, preflighting the R22 is not the messy job it can be on many helicopters. I was taught to be suspicious of any bearing that isn’t slinging a little grease, but that’s not the case for Robinson pilots.

The main rotor gearbox and drive system are easy to see and touch, and everything has a simple, rugged look. Robinson patterned the main transmission after a heavy-duty truck differential—one of the most reliable designs he could find.

Gearboxes and bearings have “Telatemps” (small stickers with calibrated material that changes color with temperature) to warn of overheating. The R22’s cabin is small but seems roomier than, say, a Cessna 152’s or Piper Tomahawk’s.

I was surprised by the comfort, and I’m a not-too-svelte guy of six-foot-two. There is room for one soft-sided suitcase under each seat, and that’s it for baggage. The windshield is big and the doors come off in seconds for hot-weather flying and improved visibility.

An overhead window in the left cabin roof allows the pilot to see out in a tight left turn. Of the R22’s many unusual features, the “T-bar” cyclic stands out. The cyclic stick emerges from the floor in the center of the cockpit, and a crossbar with a handle grip on each end teeters on top.

The pilot that’s flying moves the grip to whatever position feels comfortable above his lap, which leaves the other grip at some strange angle. I had long believed Robinson invented this cyclic to save the weight and complexity of two cyclics, but that’s only part of the reason.

Robinson also invented the T-bar cyclic to help overcome the scale effect, which is a mathematician’s way of explaining why small aircraft, boats and cars respond quickly to control inputs, while larger machines react more ponderously.

To keep the R22 helicopter from being twitchy on the controls, Robinson needed to have more cyclic travel per degree of main rotor pitch change than was possible with a conventional cyclic. Full travel of a conventional stick is limited by the distance between the pilot’s legs, but the T-bar system allows the cyclic to be moved through a much larger range of travel.

The engine in the R22 Beta is the dependable Lycoming 0-320 four-cylinder, flat-rated to 131 hp for takeoff. Flat-rating the engine down from 160 hp allows the R22 to have full power for takeoff and hover on hot days or at higher altitudes.

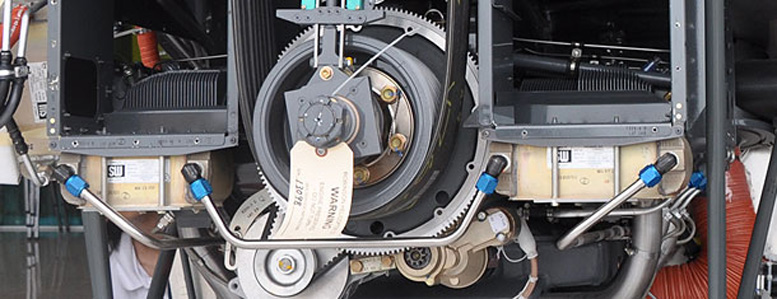

It also helps reduce wear on the engine, and consequently most of the 0-320s are reaching the recommended 2,000-hour TBO. Rotor engagement in the R22 is as easy as flipping a switch. Other piston-powered helicopters require a specific, multi-step procedure that takes time and concentration.

An electric actuator on the R22 simply pushes the engine and main rotor drive pulleys apart, tightening the drive belts to a preset tension. If the belts stretch a little in flight because of temperature changes, or because they are new, the actuator automatically moves to maintain even belt tension.

Engine and rotor rpm are displayed on a single tachometer, but instead of having two concentric needles that match when engine and rotor are in unison, the R22 tachometer uses individual needles moving over a merged central scale. At first I thought it would be tough to see when rotor and engine rpm were out of sync, but it’s not.

And the tachometer is marked in percent rpm instead of actual value, making it easier to see how far rpm has deviated from the ideal. The tachometer is electronic, light and reliable. The throttle correlator on the R22 helicopter works wonderfully.

On initial liftoff a slight twist of the throttle may be necessary to set the rpm in the middle of the green arc, but after that I was able to hover, land, take off and even recover from an autorotation without having to twist the throttle again to control rpm.

For those who want even more automatic rpm control, Robinson has developed an electronic throttle governor that moves the throttle and sometimes nudges the collective to maintain constant rpm.

The R22 displays the pendulum effect unavoidable in any teetering-rotor helicopter, meaning that the rotor disc moves more quickly than the fuselage suspended below it. This is noticeable in cruise and in landing. As the R22 nears touchdown, ground effect adds lift and slows the helicopter’s descent a few inches above the ground.

New R22 pilots tend to hang in ground effect and wobble around instead of positively lowering the collective to fly to touchdown. The sensation will be familiar to anyone who has flown the light Bell helicopters.

The R22 is quite fast, with a VNE redline airspeed of 102 knots and a typical cruise around 90 knots. Sound levels inside and out are low, making it possible to fly the Robinson over noise-sensitive areas.

The lightly loaded main rotor helps make the R22 quiet, but it demands quick pilot response in an autorotation. Because there is relatively little inertia in the main rotor, the collective must be lowered promptly to maintain rotor speed when entering the autorotation.

Once established in the autorotation the R22 glides well, so well in fact that I kept overshooting my intended landing spot. The R22 has plenty of tail rotor authority because of its unusual asymmetrical airfoil, which is more efficient in producing thrust to counteract main rotor torque.

The tail rotor is so good that I found it impossible to run out of left pedal. With the throttle rolled back first to 90-percent rpm, then 80 percent, and finally 70 percent, there was still enough tail rotor thrust to make rapid left-pedal authority.

The powerful tail rotor makes it easy to maneuver the R22 helicopter in tight spots. The helicopter does, however, fly in cruise with a slight bank angle, so a normal slip-skid ball is not good for trimming the pedals.

Instead, the R22 helicopter is fitted with yaw strings attached to the windshield center strip. If the strings are not streaming directly aft, a little adjustment of the pedals puts the helicopter back in trim.

Takeoffs require considerable nose-down pitch to accelerate to the recommended climb speed of 60 knots. Once that speed is reached, the R22 climbs and cruises at a nearly level attitude. Even at maximum cruise speed I didn’t have the nose-low sensation that predominates in some helicopters.

Because the teetering two-blade main rotor makes the R22 helicopter immune to ground resonance problems, the helicopter’s landing gear is not fitted with shock absorbers. There is, however, enough flex in the skid supports and cross members to nicely cushion a normal touchdown or even a run-on landing on rough sod.

The skids are quite short and centered under the fuselage, so run-on landings are made in a slight nose-up attitude. Hovering autorotations in the R22 demand a deft touch on the collective because the lightweight main rotor stores so little energy.

The trick is to delay your collective pull until the skids are very close to the ground and then pull the full range of collective. If you botch the hovering autorotation by pulling collective a little too early or not pulling full authority, you probably won’t hurt more than your pride.

It’s difficult to describe the flying qualities of the R22 helicopter because its control force is not as featherlight as some hydraulically boosted systems, but the controls are sensitive to even the smallest cyclic or pedal movements.

There is tremendous control power in the system, and the R22 helicopter can handle strong crosswinds or tail-winds up to 17 knots, which is on par with many larger turbine-powered helicopters.

The lightweight main rotor can lose rpm quickly during an autorotation or if the airspeed is zeroed out while maintaining a high descent rate. But with proper instruction a student can learn to avoid those circumstances.

Both the new helicopter pilot and the pilot accustomed to larger, less responsive helicopters will find the R22 helicopter a challenge to manage at first. But once you start to get the feel of the sensitive controls, the R22 is great fun to fly.

In the first few years of operation R22 helicopter pilots had a poor safety record, primarily in the training environment. To combat the problem Robinson developed its own safety program and cut the fatal accident rate by three-quarters.

Training is now involved in less than a quarter of such accidents, compared with more than half before the safety program. Robinson also recommended increasing the experience level of R22 instructors.

Robinson’s patented Tri-hinge rotor head teeters on the center hinge and cones on the outer hinges. It’s basic, lightweight, cost-effective and trustworthy—like the R22.

The company found that many helicopter instructors had just a few total hours in helicopters, and even less in the R22. If you already have a CFI rating, the FAA will issue you a helicopter CFI rating with little more than a check ride.

In order to qualify for a Robinson factory-sponsored insurance program, however, a helicopter instructor must have 500 total helicopter hours, including 50 hours in the R22, or if his total helicopter time is less than 500 hours, he must have 150 hours in the R22 helicopter.

Robinson’s goal of building a reliable helicopter has been realized. All the R22’s major components have at least a 2,000-hour overhaul or retirement life.

For a fixed fee — now about $42,000 — you can return your 2,000-, 4,000- or 6,000-hour-old R22 to the factory for a complete overhaul that includes replacing the engine with a factory-remanufactured one and installing new main rotor blades. The helicopters returned for overhaul are inserted into the production line and are almost totally rebuilt.

Every questionable part is replaced instead of repaired because it actually costs less in the manufacturing situation to install new parts instead of trying to nurse a few more hours out of an old part.

Even the R22 helicopter interior is replaced and the reworked helicopter gets a new paint job, all in the predetermined price. That’s a good deal and the reason overhauls are now up to two per week.

With fuel flows between seven and eight GPH, and little periodic maintenance required between overhauls, Robinson calculates that you can fly an R22 helicopter for about $51 per hour, of which $21 is for the full factory overhaul reserve.

Frank Robinson’s R22 helicopter is fast, simple, reliable and chops the cost of instruction, observation and personal flying down to size. Much of the helicopter world already knows that. I’m just sorry I waited so long to find out for myself.

The helicopter flown for this report was equipped with a Bendix/King KY197com transceiver that also provides intercom function, basic VFR flight instruments, navigation, anticollison lights and landing lights as standard equipment. A carburetor air-temperature gauge, digital OAT gauge and dual controls are also standard.

Optional equipment included a Bendix/King KT76A transponder with an altitude encoder and a cabin heater. Optional equipment increased the basic empty weight to 835 poundsfrom 826, leaving a useful load of535 pounds. Equipped list price was $101,600.

| Robinson R22 Beta Helicopter Specifications | |

|---|---|

| Standard price | $98,850 |

| Engine | Lycoming 0-320-B2C, flat-rated at 131 hp for takeoff |

| TBO | 2,000 hrs |

| Main rotor diameter | 25.2 ft |

| Height | 8.9 ft |

| Skid width | 6.3 ft |

| Length | 28.8 ft |

| Seats | 2 |

| Max takeoff weight | 1,370 lbs |

| Standard empty weight | 826 lb |

| Useful load | 544 lbs |

| Max landing weight | 1,370 lbs |

| Minimum solo-pilot weight | 130 lbs |

| Disc loading | 2.7 Ibs/sq ft |

| Power loading | 10.5 lbs/hp |

| Standard usable fuel | 19.2 gal |

| Optional usable fuel | 10.5 gal |

| Max rate of climb | 1,000 fpm |

| Ceiling (service) | 14,000 ft |

| Hover in ground effect | 6,970 ft |

| Hover out of ground effect | 5,200 ft |

| Max cruise speed | 96kts |

| Max speed (VNE redline) | 102 kts |

| Average fuel flow | 7.5 gph |

| Endurance | 2.5 hrs |

Be the first to comment on "Robinson Tri-Hinge Rotor Head R22 Helicopter"