Helicopter Engine Options – Turbine

Interesting Thoughts on the Turbine Engine

People the world over are interested in turbine power and with some government interest in Asia and Europe, I’ve been working harder than ever, I now provide services to a number of projects, turbine Execs, Mini 500s, conversions for some certified ships and lets not miss things that fly, float, scoot and drive.

VIDEO: Rotorway JetExec: Start-up / Flight / Landing

There is a lot of misunderstanding of the turbine engine, fuel burn, useful load and the comparison of efficiency between piston and turbine power. Education is your best defense, so read, ask questions, and talk to people who have done well and have flown a turbine project.

So now a class on Basic Turbine Horsepower / work / going up.

The Piston Engine

We can break it down into events or cycles, a simple way to show how power is produced, INTAKE, COMPRESSION, POWER, EXHAUST.

VIDEO: Piston Powerplant – Helicopter Components

In a piston engine the cylinder is used to convert heat energy to expand air to push a piston down and turn a crank shaft.

When the cycles are finished the heated gasses are exchanged for unburnt air and fuel for a repeat of the cycles.

To explain step by step:

▣ Event 1: Intake valve opens, piston moves down sucking fuel and air into the cylinder.

▣ Event 2: Intake valve closes and the piston moves up to compress mixture into a more powerful condition.

▣ Event 3: A spark lights off the mixture and burns expanding the air inside and pushes the piston down producing power.

▣ Event 4: Exhaust valves open and the piston pushes out the used gasses, at the top of the stroke the exhaust closes.

And the events continue over and over and over. Four events in the same are at different times. One power stroke in four cycles, not too good for efficiency.

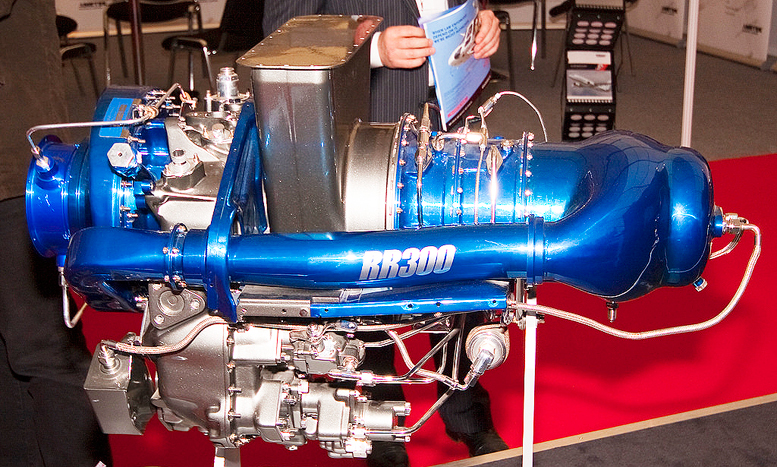

NOW THE TURBINE: Centrifugal compressor Type

VIDEO: Allison 250 Engine Cutaway Full Start

The events in a turbine are continuous (at the same time) but at different locations in the engine. The compressor draws in and speeds up the air, slinging it into the plenum area compressing it, from the plenum the air is directed by guide vanes to the combuster where the pressure is reduced and fuel is added and burned.

The expanding gasses from the fire can’t go against the flow of air and escapes the combuster through the turbine nozzles that speeds up the velocity of the exiting gasses turning the turbine (like a water wheel) and the exhaust directs the used gasses out of the engine.

The cycles are continuous, the moving parts few, 60% to 70% of the air is used to cool the insides. The oil pump for lubrication and fuel pump/control are the only power using items, (almost none).

When geared to a shaft the mechanical energy is multiplied at each reduction of RPM (same horse power, more torque). Like Low Gear!!!

The Comparison: Piston vs Turbine

Piston: Lycoming 0-320 120 to 150hp, weight to run 300lbs., fuel for 2 ½ hours, 178 lbs. total engine/fuel for 2 ½ hours, 478 lbs. to make 150hp.

Turbine: Airesearch 36-55c 145 hp, weight to run 95lbs; fuel for 2 ½ hours 163 lbs. total engine/fuel for 2 ½ hours 258 lbs. to make 145hp. Now tell me how it can’t work.

Even if the fuel burn in a turbine is greater than a piston engine, the low weight more than offsets the weight to fuel required to fly. If you can save 200lbs and burn 60lbs more fuel your useful load is still increased by 140lbs.

Allison 250-c 20B: if you have an engine weight of 160 lbs @ 417 hp, burning 25 GPH (weight is every piece to run), you have a total 325lbs producing 417 hp for one hour. This engine is used in Hughes 500 and Bell 206 helicopters.

TBO on the mini turbine is 1370 hrs (1st stage wheel and nozzle) and a TBO of 2500 for the Maxi Turbine (all the stages in the “hot section”). Lycoming 0-320: Now you have an engine weight of 300 lbs @ 150hp burning 10 AGL per hour. Total of 366 lbs producing 150hp (This does not include oil cooler, alternator baffles and fan for helicopter use).

Now the costs of the care and feeding of your power plant: with a piston engine it is best to change the oil every 25 hours, if not you chance a possible sticky valve, to change a jug is a pain and oil is cheap.

Then at 100 hours (a good number for a check up) you do compression checks, mag timing check and adjustments, filters, plugs cleaned or changed and so on. And if it’s an auto conversion or a Rotorway rubber winder, you’re still working the bugs out of it. Most engines for your “toy” is say around 5 to 15 thousand dead Washingtons, Ouch!

What was it used for, and who has it. I’ve found Trade-A-Plane a good source along with others so read up, ask questions, look. Does the person selling you that engine really have an idea as to how to match the best engine to your machine, or is he producing profit at your expense. More on governers and reductions later.

Turbine Powered Mosquito Kit Helicopter

VIDEO: XET Full Length-RM

Fly Safe, and Keep’em Topped Off!

Be the first to comment on "Turbine Helicopter Engine Options"